PlasmaAir AG: Pioneering Sustainable Solutions

Welcome to PlasmaAir AG, a German leader in plasma technology and air pollution control with over 20 years of experience. As pioneers in designing, implementing, and commercializing advanced plasma processes, we specialize in the development of plasma sources for applications in waste disposal, pyrolysis, CO2 mitigation, and hydrogen production through methane decomposition.

Collaborating closely with esteemed research institutes and universities, PlasmaAir efficiently addresses complex problems, drawing on our expertise in small-scale production to deliver flexible solutions for specific exhaust air challenges. At PlasmaAir, research and development are paramount, fostering innovation through collaborative R&D initiatives with academic institutions.

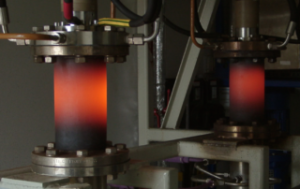

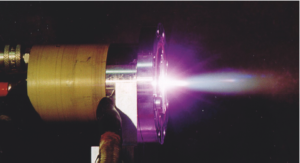

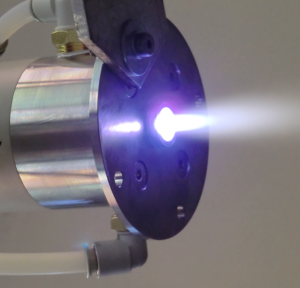

Discover the Future of Electrification Across Industries with Plasma Torch Innovation. At PlasmaAir AG, we lead the charge in revolutionizing industrial processes through cutting-edge plasma torch technology. By utilizing thermal plasma torches, we harness the elevated temperatures generated by the plasma to facilitate diverse applications in electrifying processes.

Industries We Serve:

Cement Manufacturing: Transforming production methods for reduced carbon footprints and enhanced efficiency.

Glass Manufacturing: Revolutionizing glass production with cleaner heating methods, minimizing environmental impact.

Metallurgical Industry: Optimizing metal smelting and refining with advanced plasma torch solutions for energy efficiency.

Chemical Processing: Elevating sustainability in chemical processes, reducing reliance on fossil fuels.

Waste Incineration: Contributing to sustainable waste management with efficient incineration powered by plasma torches.

Key Advantages

Carbon Neutral: Reducing reliance on fossil fuels for a cleaner, greener future.

Enhanced Efficiency: Optimizing energy use for improved operational efficiency.

Join us in shaping a sustainable future with PlasmaAir AG