Development of a plasma burner for direct ignition of coal in power plant burners

The project “Increasing flexibility through electric ignition of power plant burners (FlexIgnite)”, funded by the BMWi as part of the German government’s 6th Energy Research Program under the COORETEC initiative, was carried out in cooperation with the IFK and IGVP at the University of Stuttgart and the companies Mitsubishi Hitachi Power Systems Europe (Duisburg) and Lausitz Energie Bergbau AG (Cottbus).

The aim of this project was to develop, test and validate the DC plasma ignition technology for solid fuels (biomass, lignite and hard coal) to increase the flexibility of power plants with regard to minimum load, load change speed and fuel use.

Detailed information can be found here.

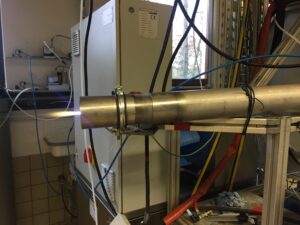

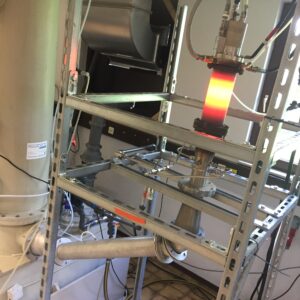

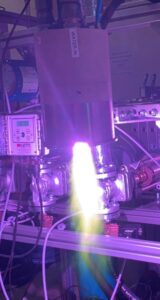

Development of an arc-heated, radiation-cooled,

thermal water vapor plasma system for the treatment of PFC emissions

The project “Radiation-cooled, thermal water vapor plasma system for the treatment of perfluorinated exhaust air streams (StrahlWaBe)”, funded by the BMBF as part of the KMU-innovativ: resource and energy efficiency funding program with a focus on “energy efficiency / climate protection”, was carried out in cooperation with the ISWA at the University of Stuttgart.

The objective of the project was the development of an arc-heated, radiation-cooled, thermal water vapor plasma system with a high-temperature reaction zone for the treatment of emissions of PFCs, as they occur in etching and cleaning processes in the semiconductor industry, in aluminum smelting or refrigerator disposal.

You can find detailed information here.

Optimization of exhaust air purification systems in MBT plants

The follow-up project “Energy-efficient exhaust air treatment 2 (EnAB 2) – Energy-efficient exhaust air treatment in mechanical-biological waste treatment plants”, funded by the BMWi as part of the German government’s 6th Energy Research Program, was carried out in cooperation with RWTH Aachen University, the University of Stuttgart and the company MKW (Großefehn).

The aim of this R&D project was to significantly reduce the energy required for mechanical-biological waste stabilization.

Detailed information can be found here.

The guidelines developed as part of the project can be found here.

Energy-efficient exhaust air treatment in mechanical-biological waste treatment plants

The “Energy-efficient exhaust air treatment (EnAB)” project, funded by the BMWi as part of the German government’s 6th Energy Research Program, was carried out in cooperation with RWTH Aachen University, the University of Stuttgart and the company MKW (Großefehn).

The aim of the project was to increase the energy efficiency of MBT by using alternative and innovative exhaust air treatment methods.

In EnAB, four project partners researched measures aimed at increasing energy efficiency and process efficiency in MBT plants. The objectives of EnAB were to be achieved on the one hand by using alternative exhaust air treatment plants and on the other hand by modifying the operating modes in the mechanical (MA) and biological (BA) treatment stages. In the project, large-scale test series were carried out in an existing MBT plant with an annual treatment capacity of approx. 60,000 Mg. In addition, partial exhaust air flows from the BA were treated in a pilot plant with a modified exhaust air management system.

Detailed information can be found here.

Process combination for the treatment of exhaust air flows

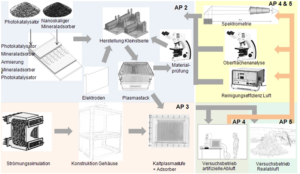

The BMWi-funded ZIM project “Functionalized mineral composites as a dielectric barrier in the process combination of dielectrically impeded gas discharge, mineral adsorber and bioscrubber for the treatment of exhaust air streams (MiCoPlAST)” was carried out in cooperation with the University of Stuttgart, RWTH Aachen University and Richter Akustik & Design (Melle).

The aim of this research project was the production of functionalized composite panels as a dielectric barrier for a non-thermal plasma discharge (NTP) for the treatment of exhaust air streams containing VOCs.

Various parameters were investigated during development, such as a hydrophobic material property. Moisture in the exhaust air has emerged as a significant problem in previous projects and has led to discontinuous operation. This was to be prevented and remedied using new materials and surface treatments. Further options such as doping with catalytically effective materials should enable an increase in efficiency.

You can find detailed information here.

Thermal plasma systems for the treatment of odor-intensive exhaust air flows containing methane and VOCs

The research project “Treatment of odorous, methane- and VOC-containing exhaust air streams by a process combination of non-thermal plasma, mineral adsorber and scrubber stage – A combined Plasma-Adsorber-Scrubber System or Treatment of intensively smelling Crude gases (PlASTiC)”, funded by the BMBF as part of the KMU-innovativ: Ressourcen- und Energieeffizienz Schwerpunkt “Energieeffizienz / Klimaschutz” funding program, was carried out in cooperation with the University of Stuttgart and the companies DURTEC GmbH and Liutec – Labor für innovative Umwelttechnik.

The aim of this project was to develop and optimize a modular exhaust air purification process for the simultaneous reduction of emissions of VOCs (including methane), odorous substances and gaseous inorganic pollutants, such as those encountered in animal husbandry, sewage sludge drying or waste composting.

You can find detailed information here.

Development of a fine dust separator for wood firing systems

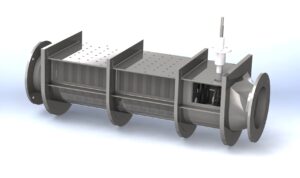

The DBU-funded research project “Development of an electrostatic precipitator for small-scale biomass combustion plants – 1st phase” was carried out in cooperation with the IFK at the University of Stuttgart.

The aim of the project was to develop a compact and reliable electrostatic precipitator for small biomass combustion plants.

The prototype of an electrostatic precipitator resulting from this project was the basis for the subsequent funding project “Investigation of the relationship between separation efficiency and particle properties in electrostatic precipitators for small biomass furnaces”.

Detailed information can be found here.

Further development of a fine dust separator for wood firing systems

The DBU-funded research project “Investigations into the relationship between separation performance and particle properties in electrostatic precipitators for small biomass furnaces” was carried out in cooperation with the IFK at the University of Stuttgart. Extensive measurements were carried out with the prototype of the electro fine dust separator (EFA) on the test stand at the IFK.

On June 7 and 8, 2016, 190 pioneering environmental projects were presented in the park of Bellevue Palace during the Week of the Environment. PlasmaAir was selected from over 600 applications to present this DBU-funded research project there.

Flyer on the project: Electrostatic precipitator – EFA (page 1), Electrostatic precipitator – EFA (page 2)

Detailed information can be found here.

Anti-clogging measures PU foam

The research project “Investigations into ‘anti-clogging’ measures for PU foam carriers in biotrickling filters for exhaust air purification”, funded by the BMBF as part of the KMU-innovativ: resource and energy efficiency funding program with a focus on “energy efficiency / climate protection”, was carried out in cooperation with the University of Stuttgart and the company EMW filtertechnik GmbH.

The aim of the project was to investigate the prevention of clogging events of PU foam carriers due to excessive biomass formation in biotrickling filters for the biological treatment of exhaust air streams with high specific loads of organic solvents.

Detailed information can be found here.

Non-thermal plasma for exhaust air purification

The BMWi-funded ZIM project “Process for the treatment and material/thermal recycling of industrial exhaust air flows” was carried out in cooperation with the ISWA at the University of Stuttgart.

In this research project, a two-stage exhaust air purification process was developed, consisting of a biotrickling filter and a modified cold plasma stage.

You can find detailed information here.

Water vapor plasma source for the treatment of waste gases from plastics pyrolysis

The BMWi-funded ZIM project “Development of a water vapor plasma source for the treatment of waste gases from plastic pyrolysis (WaAAKu)” is being carried out in cooperation with the University of Stuttgart.

The aim of this R&D project is the successful development of a high-performance steam plasma burner for plastic pyrolysis in order to utilize plastic waste according to the “waste-to-energy” principle in addition to recycling.

Coating for glass fibers in the glass fiber spinning process

The BMWi-funded ZIM project “Development of a new type of coating for glass fibers in the glass fiber spinning process (PlasmaSizing)” is being carried out in cooperation with the University of Stuttgart, RWTH Aachen University and Plasmatreat GmbH (Steinhagen).

The aim of this R&D project is the successful and innovative development of a coating for glass fibers. The exhaust air produced in this process is potentially problematic. In the PlasmaAir AG sub-project, a test facility is to be developed to treat this exhaust air.

Energy-efficient cascade use of biogenic waste

The BMWi-funded project “Energy-efficient cascade utilization of biogenic waste taking into account new requirements for exhaust air treatment and compost quality (EKaBio)” was carried out in cooperation with the University of Stuttgart, RWTH Aachen University and the companies MKW – Materialkreislauf- und Kompostwirtschaft GmbH & Co. KG (Großefehn), pbo Ingenieursgesellschaft mbH (Aachen) and STRABAG Umwelttechnik GmbH (Düsseldorf) and is a follow-up project to the previous EnAB and EnAB2 research projects.

In the joint project EKaBio, large-scale tests were carried out to optimize the operation of cascade plants with regard to material flow management, emission reduction and energy efficiency increase.

The exhaust air analyses have shown that the limit values of the TA-Luft are complied with. It was also shown that methane in particular was a major component of the total carbon content (TOC). In contrast to other C components, methane cannot be broken down in the biofilter. In addition, methane cannot be effectively removed from the exhaust air stream under economically justifiable conditions with the current state of the art.

You will find detailed information here.